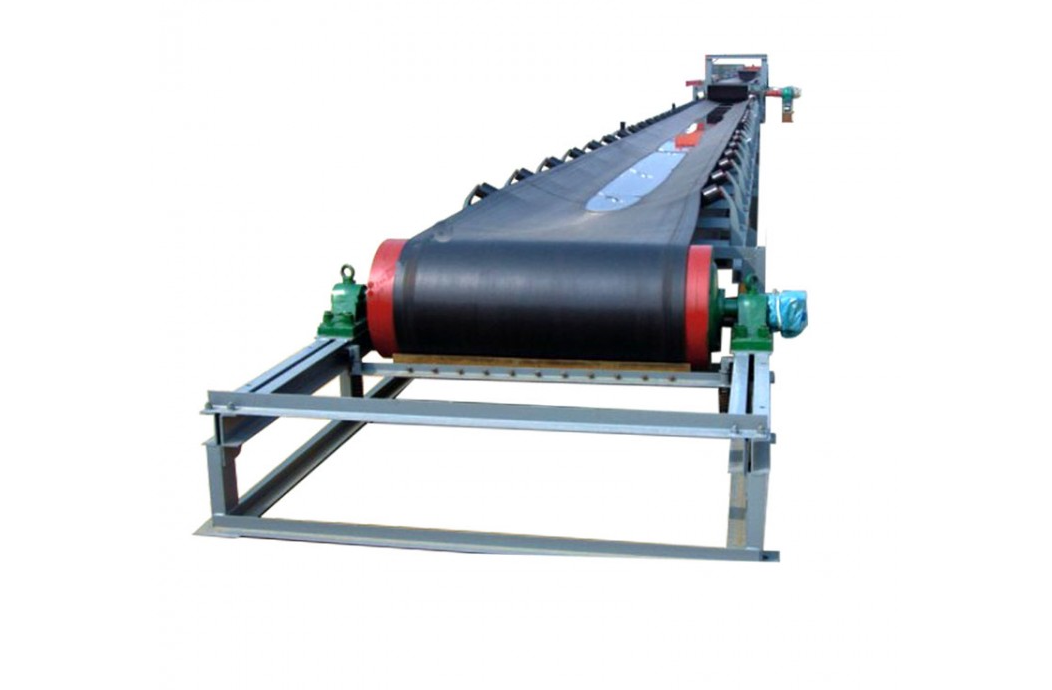

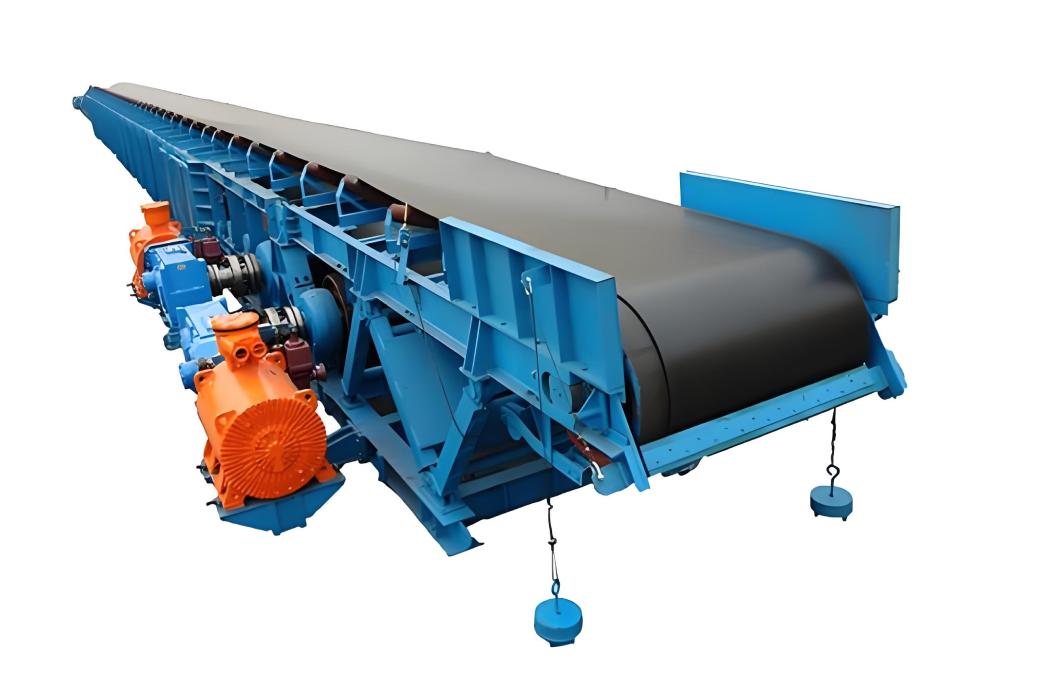

Tripper Conveyor

Capacity: 450-5687t/h

It is mounted on rails and moves horizontally along the conveyor structure, allowing materials to be discharged at any desired point by lifting a discharge chute or through a pivoting discharge mechanism.

Tripper conveyors are widely used in bulk storage applications, stockpiling systems, and in facilities requiring flexible material distribution, such as coal yards, cement plants, and power stations. They enhance the efficiency of storage and reclaiming operations by eliminating the need for multiple fixed conveyors or stackers

Advantages

Product Advantages and Features

Better Quality Production

To give you peace of mind

Technical Data

| Model | Belt Width (mm) | Capacity (t/h) | Travel Length (m) | Discharge Type | Control Mode | Power Drive |

| TC-800 | 800 | 300 – 600 | ≤ 80 | Fixed chute / Rotating chute | Manual / Remote | Motor + Reducer (rail-mounted) |

| TC-1000 | 1000 | 500 – 1000 | ≤ 120 | Single / Bi-directional | Remote / Automatic | Motor + Hydraulic Coupler |

| TC-1200 (Custom) | 1200 | 800 – 1500 | ≤ 150 | Pivoting chute / Dual chute | PLC Intelligent Control System | Motor + Coupling + Variable Speed Drive |

Note: Model-specific details available upon request. Please contact technical support.

Enterprise Services

- Factory original price

- Global after-sales service

- Free installation and maintenance guidance

- 24-hour online customer service

-

28

28 years of development

-

160

Sold to more than 160 countries

-

500

More than 500 long-term partners

-

50

Covering an area of 500,000 square meters