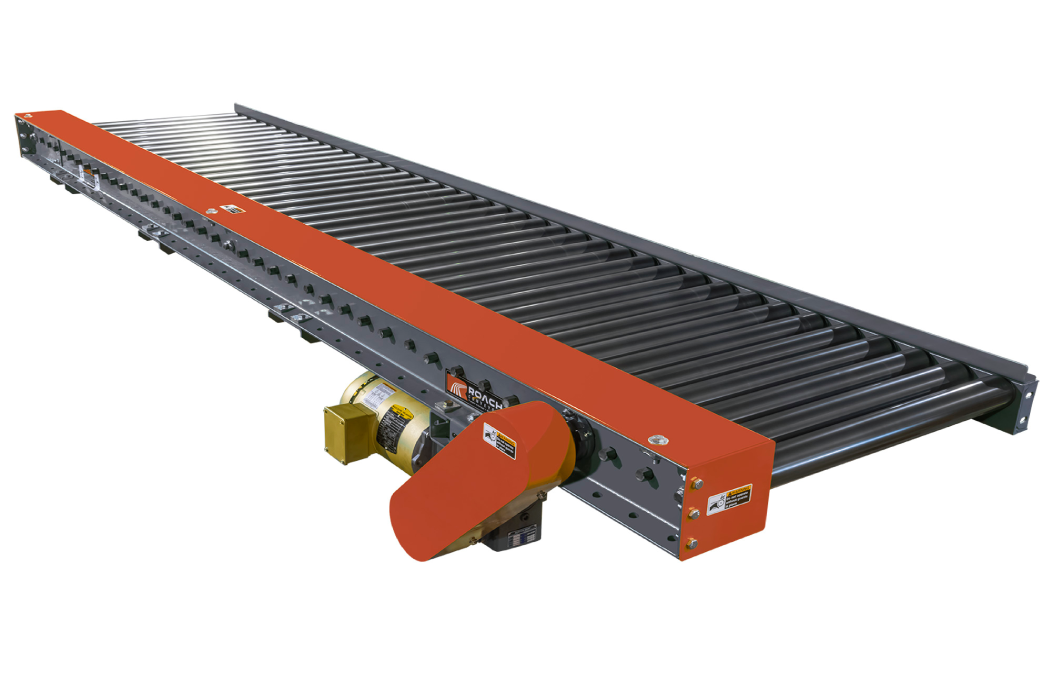

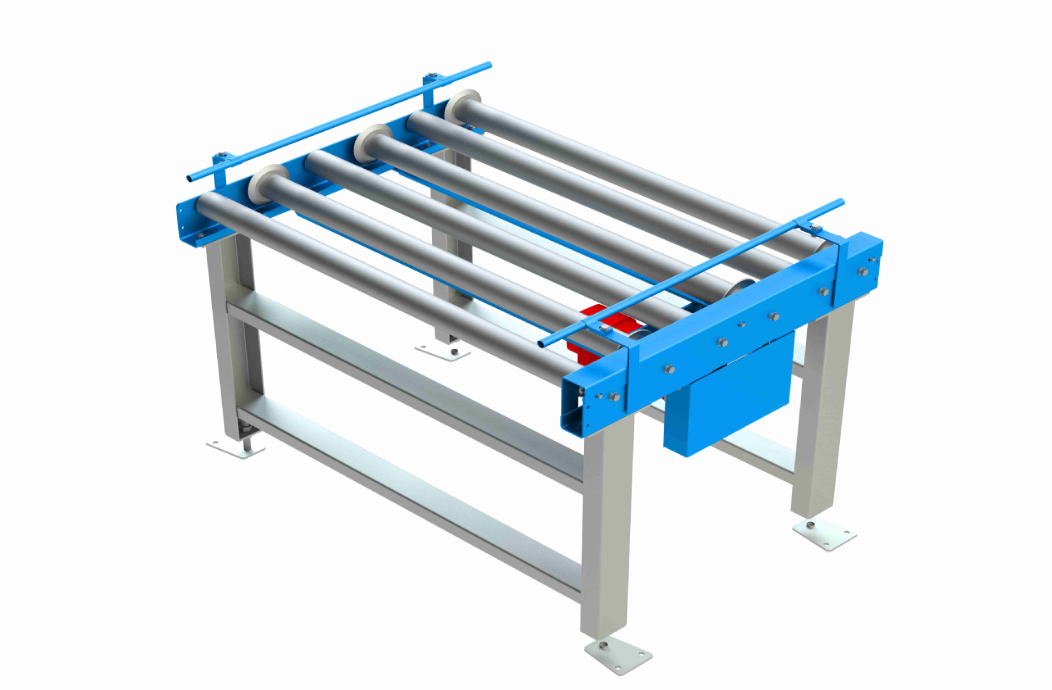

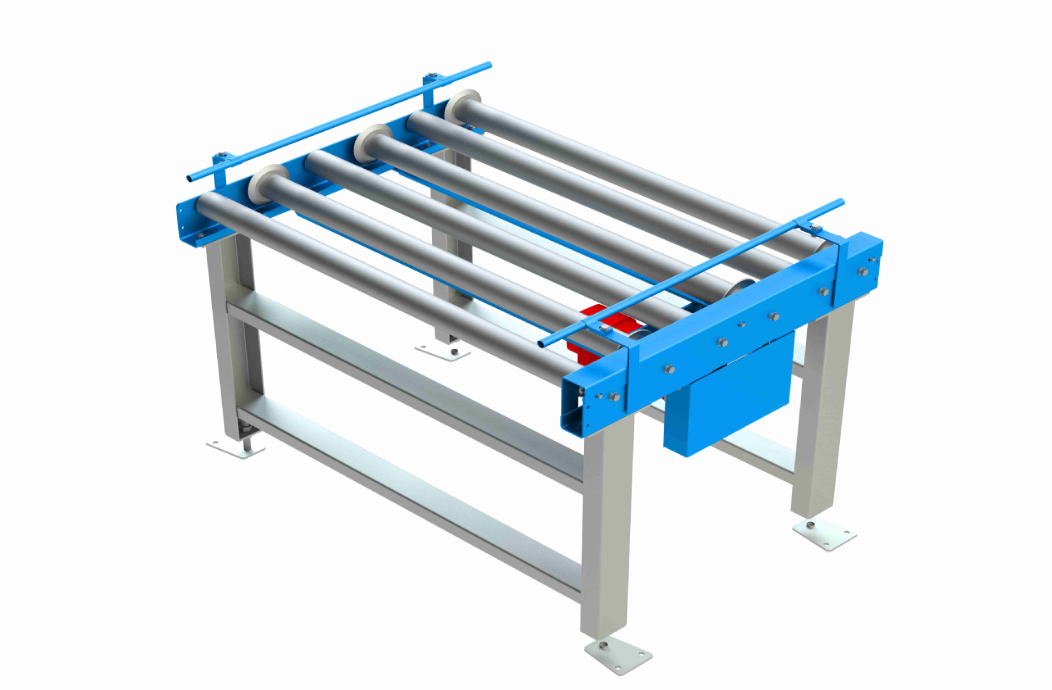

Accumulation type roller conveyor

Capacity: 450-5687t/h

By arranging friction drive, clutch structure or partition control system between the rollers, the materials can stop, wait or advance intermittently in an orderly manner without stopping the operation of the entire conveyor line. It is widely used in automated production and sorting systems that require tempo control, segmented conveying or collision prevention.

Accumulation type roller conveyor is widely used in: logistics/e-commerce sorting center, electronic/home appliance assembly line, automobile parts conveying line

Advantages

Product Advantages and Features

Better Quality Production

To give you peace of mind

Technical Data

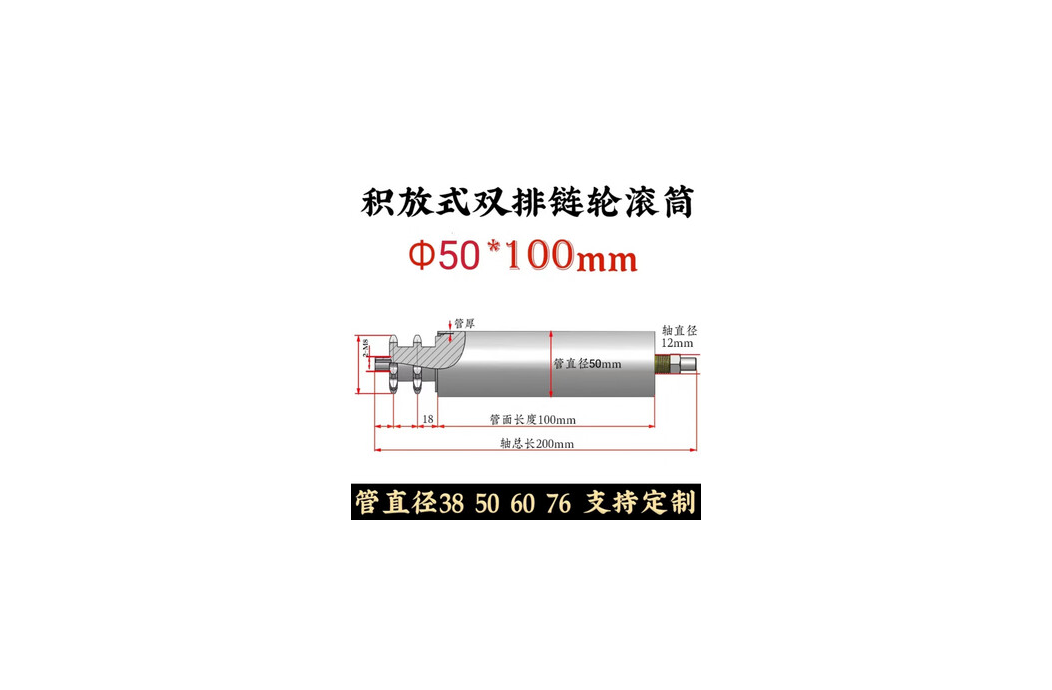

| Model | Roller diameter (mm) | Effective width (mm) | Accumulation section control method | Drive method | Carrying capacity (kg/m) | Applicable materials |

| ARC-60/Zone-Light | Ø60 | 500–800 | Friction roller accumulation control | Single motor + partition clutch structure | ≤80 | Cartons, small items, parcels |

| ARC-76/Sensor-Drive | Ø76 | 600–1000 | Photoelectric induction + segmented drive control | Multi-motor drive +PLC control | ≤300 | Medium weight box, pallet |

| ARC-89/Heavy-Buff | Ø89 | 800–1200 | Pneumatic blocking + induction signal control | Multi-chain drive + variable frequency speed regulation | ≤800 | Heavy duty pallet, auto parts |

Note: Model-specific details available upon request. Please contact technical support.

Enterprise Services

- Factory original price

- Global after-sales service

- Free installation and maintenance guidance

- 24-hour online customer service

-

28

28 years of development

-

160

Sold to more than 160 countries

-

500

More than 500 long-term partners

-

50

Covering an area of 500,000 square meters