The trough roller bracket (also known as an idler bracket) is a key component in a conveyor system. It is used to support and stabilize the idler rollers that carry the conveyor belt

The trough roller bracket (also known as an idler bracket) is a key component in a conveyor system. It is used to support and stabilize the idler rollers that carry the conveyor belt. These brackets ensure that the conveyor rollers function properly, which in turn guarantees the smooth operation of the conveyor belt system.

Support the Idler Rollers:

The primary function of the trough roller bracket is to support the idler rollers. These rollers are placed across the conveyor system to carry the weight of the conveyor belt and materials being conveyed.

Ensure Stable Operation:

The bracket helps maintain the stability of the rollers and ensures that the conveyor belt runs in a straight line without deviation, reducing wear and ensuring consistent performance.

Prevent Material Spillage:

A properly installed trough roller bracket can prevent material from spilling out of the conveyor system by supporting the belt and maintaining the correct angle of the idlers.

Reduce Wear and Tear:

By maintaining proper alignment and reducing friction between the conveyor belt and idlers, the trough roller bracket helps to reduce wear and extend the lifespan of both the belt and the rollers.

Fixed Bracket:

Purpose: The fixed bracket is used for stationary applications where the position of the idler rollers does not require adjustment.

Characteristics: Common in standard, straight conveyor lines where only basic support is needed.

Adjustable Bracket:

Purpose: These brackets allow for the adjustment of the height and angle of the idler rollers.

Characteristics: Suitable for conveyor systems that require regular adjustments to maintain proper belt tension or to accommodate varying load conditions.

Sliding Bracket:

Purpose: Sliding brackets allow the idler rollers to slide within the bracket, providing flexibility and compensating for pressure or impact on the rollers.

Characteristics: Typically used in longer conveyor systems where the rollers need to adjust dynamically based on the system's requirements.

Suspension Bracket:

Purpose: Suspension brackets hold the idler rollers above the conveyor belt, which is useful for high-clearance applications.

Characteristics: These brackets are used when there are height constraints or the conveyor system needs to operate at elevated positions.

The material selection for the brackets is crucial for ensuring durability and functionality, especially under heavy loads or harsh operating conditions.

Steel: Steel is the most common material used for trough roller brackets due to its strength and durability. Steel brackets can withstand heavy loads and are suitable for most industrial environments.

Stainless Steel: For environments where the brackets will be exposed to moisture or corrosive substances (such as food or chemical industries), stainless steel is preferred due to its excellent corrosion resistance.

Plastic or Rubber: In lighter-duty applications, plastic or rubber brackets may be used. These materials are more flexible and resistant to certain chemicals, but they are generally not as strong as metal options.

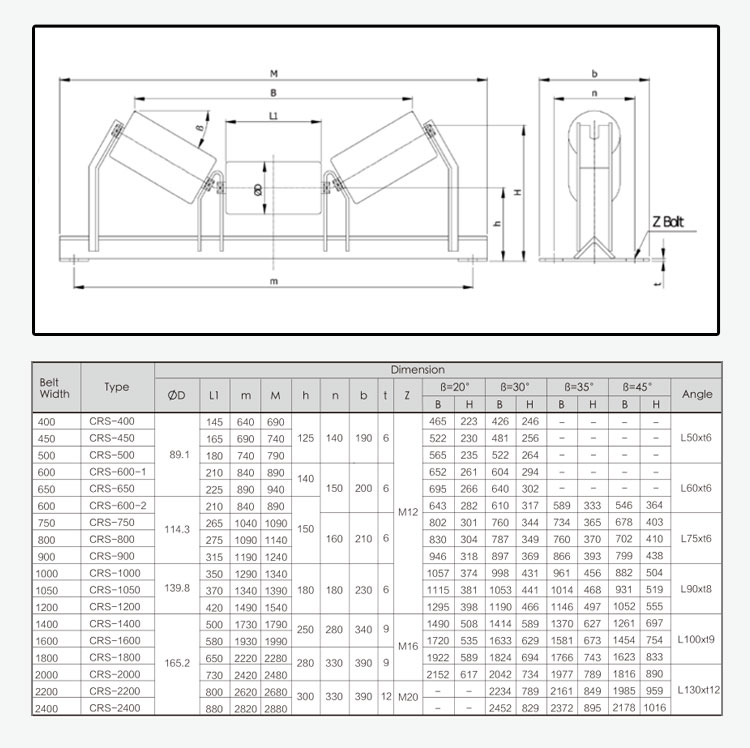

A typical trough roller bracket consists of the following components:

Main Frame: The main structural part that holds the idler roller in place. It is usually made of metal and designed to support heavy loads.

Roller Mounting Seat: The seat that holds the idler roller securely in place. The roller is mounted on this seat to ensure smooth operation.

Adjustment Mechanism: For adjustable brackets, this part allows you to change the height or angle of the idler roller to achieve the desired conveyor belt alignment.

Fasteners and Hardware: The brackets include various fasteners such as bolts, nuts, and washers, which are used to secure the bracket to the conveyor frame.

Load Capacity: The bracket must be selected based on the weight of the conveyor belt and materials being transported. Make sure the bracket has a sufficient load capacity to support the system.

Durability: The bracket must be made from durable materials that can withstand wear and tear. For high-impact or heavy-duty applications, choose a bracket made of steel or stainless steel.

Corrosion Resistance: In harsh environments (such as chemical plants or outdoor installations), corrosion resistance is crucial. Stainless steel or coated metal brackets are ideal in these situations.

Adjustability: If your conveyor system requires regular adjustments for tension or alignment, an adjustable bracket would be the most suitable choice.

Installation Environment: Consider the environment in which the conveyor system will operate. If there are space constraints or the system is operating in a high-temperature environment, specialized brackets may be required.

Trough roller brackets are widely used in various industries, including:

Mining: For transporting heavy ores, coal, and minerals.

Ports: For handling bulk materials like coal, grain, and other bulk goods.

Steel Plants: To move raw materials, scrap, and finished steel products.

Construction: For transporting aggregates, sand, and cement in building projects.

Food and Agriculture: For conveying grains, packaged food products, and other materials in the food industry.

Q: Are you a factory or trading company?

A: We are a factory and have export license. Besides, our factory has a number of product lines to provide products with stable production capacity for customers in delivery time.

Q: What information do I need to provide in order to confirm the conveyor rollers order?

A: We work with technical drawings for any non-standard products. If the order is for standard parts, you only have to provide us with the part number so we may define the parts of the order.

Q: Do you have the products in stock?

A: No. All the products are produced according to your order.

Q: Can you produce the hose with my own brand?

A: Yes, we have been offering OEM services to famous manufacturer for several years. Please send email to talk about details.

Q: How long is your delivery time?

A: Generally it is 7-30 days, details depend on your order quantity.

Q: How does your factory do regarding to quality control?

A: Quality is priority. We always attach great importance to quality control from beginning to the end of the production. Every batch conveyor rollers will be carefully inspected before it's packed for shipment.

Q: Can I order a sample?

A: Of course. We can offer regular model roller sample for free, but the freight cost shall be borne by your side. If you want

customized model sample, we'd like you to bear the charge for sample and freight.

Q: What’s benefit will I get?

A: Your client satisfied on the quality.

Your client continued orders.

You can get good reputation from your market and obtain more orders.