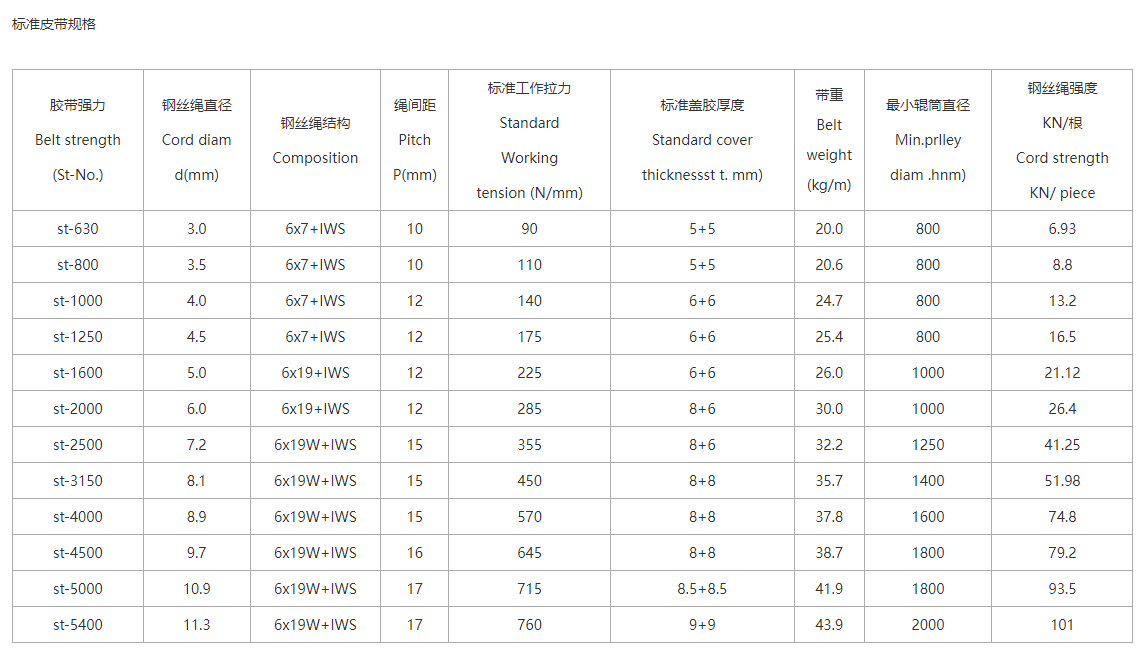

A Steel Wire Core Conveyor Belt is a type of heavy-duty conveyor belt reinforced with a core of steel wire. The steel wire core provides the belt with exceptional tensile strength, making it highly suitable for transporting heavy, bulky, or abrasive materials over long distances.

A Steel Wire Core Conveyor Belt is a type of heavy-duty conveyor belt reinforced with a core of steel wire. The steel wire core provides the belt with exceptional tensile strength, making it highly suitable for transporting heavy, bulky, or abrasive materials over long distances. These belts are commonly used in industries that require high durability, strength, and resistance to harsh operating conditions, such as mining, construction, and heavy manufacturing.

Steel Wire Core Construction: The defining feature of a steel wire core conveyor belt is its strong steel wire reinforcement, which is embedded within the belt structure. This reinforcement provides significant tensile strength, ensuring that the belt can handle heavy loads and harsh environments without failure.

High Tensile Strength: The steel wire core allows the belt to withstand high tension during operation, making it ideal for conveying heavy or bulky materials such as ores, coal, gravel, and construction materials. The tensile strength of the steel wire helps the belt maintain its integrity even under high-stress conditions.

Durability and Wear Resistance: Steel wire core belts are designed to be highly durable and resistant to abrasion. This makes them ideal for applications where the conveyor system is exposed to abrasive materials or tough operating conditions, such as mining and quarrying.

Heat and Flame Resistance: Steel wire core conveyor belts are typically more resistant to heat and flames than standard rubber belts. This makes them suitable for use in environments where high temperatures or fire hazards are present, such as in coal handling or steel mills.

Long Service Life: Due to the strength and durability of the steel wire core, these conveyor belts have a longer service life compared to belts with fabric or other types of reinforcement. The steel reinforcement reduces wear and tear, minimizing the need for frequent replacements.

High Load Capacity: The strength of the steel wire allows these belts to carry heavy loads over long distances without stretching or breaking. This makes steel wire core belts suitable for use in demanding industries where heavy loads need to be transported continuously.

Mining: Steel wire core conveyor belts are widely used in the mining industry for transporting heavy and abrasive materials such as coal, ores, and minerals. The high tensile strength and durability make them well-suited for the tough and demanding environment found in mining operations.

Cement and Construction: In cement production and construction sites, steel wire core belts are used for transporting large volumes of raw materials like limestone, gravel, and cement. Their durability and ability to handle heavy loads make them essential for construction and material handling in these industries.

Power Plants: Steel wire core belts are often used in power plants for transporting coal, biomass, and other heavy materials. The belts’ ability to operate in high-temperature environments and carry heavy loads makes them ideal for power plant operations.

Steel Mills and Foundries: In steel mills, foundries, and other industrial environments with high temperatures, steel wire core conveyor belts are used to move hot materials and scrap metal. Their flame resistance and durability are critical in such applications.

Port and Harbor Handling: Steel wire core belts are used in ports and harbors to transport bulk materials such as coal, iron ore, and other heavy cargo. Their robustness ensures safe and efficient transport over long distances in these demanding environments.

Exceptional Strength: The steel wire core provides the belt with a high level of tensile strength, allowing it to carry very heavy loads without stretching or breaking. This makes the belt ideal for transporting large quantities of materials over long distances.

Resistance to Abrasion: The steel reinforcement helps the belt resist wear and abrasion, extending its service life even in harsh environments where materials are abrasive, such as mining and construction.

Heat and Flame Resistance: Steel wire core belts are resistant to high temperatures and flames, making them ideal for industries like steel manufacturing, power generation, and mining where heat exposure is common.

Long Service Life: The combination of steel wire reinforcement and durable rubber or polymer cover materials ensures that the belt can withstand harsh conditions over an extended period, reducing downtime and maintenance costs.

Enhanced Stability: The steel wire core provides added stability to the conveyor belt, reducing the risk of deformation or elongation under high load conditions. This ensures smooth operation and reliable performance.

Reduced Maintenance: Due to their durability and strength, steel wire core conveyor belts require less maintenance and fewer replacements, which results in lower operational costs and less downtime for conveyor systems.

Q: Are you a factory or trading company?

A: We are a factory and have export license. Besides, our factory has a number of product lines to provide products with stable production capacity for customers in delivery time.

Q: What information do I need to provide in order to confirm the conveyor rollers order?

A: We work with technical drawings for any non-standard products. If the order is for standard parts, you only have to provide us with the part number so we may define the parts of the order.

Q: Do you have the products in stock?

A: No. All the products are produced according to your order.

Q: Can you produce the hose with my own brand?

A: Yes, we have been offering OEM services to famous manufacturer for several years. Please send email to talk about details.

Q: How long is your delivery time?

A: Generally it is 7-30 days, details depend on your order quantity.

Q: How does your factory do regarding to quality control?

A: Quality is priority. We always attach great importance to quality control from beginning to the end of the production. Every batch conveyor rollers will be carefully inspected before it's packed for shipment.

Q: Can I order a sample?

A: Of course. We can offer regular model roller sample for free, but the freight cost shall be borne by your side. If you want

customized model sample, we'd like you to bear the charge for sample and freight.

Q: What’s benefit will I get?

A: Your client satisfied on the quality.

Your client continued orders.

You can get good reputation from your market and obtain more orders.