A Rubber Conveyor Belt is a widely used type of conveyor belt that is designed to transport a variety of materials over both short and long distances.

A Rubber Conveyor Belt is a widely used type of conveyor belt that is designed to transport a variety of materials over both short and long distances. These belts are composed of layers of rubber-coated fabric, offering excellent durability, flexibility, and resistance to wear, making them suitable for heavy-duty applications in a wide range of industries. Rubber conveyor belts are known for their high load capacity, resistance to impact and abrasion, and adaptability to different environments and materials.

Rubber Coated Fabric Construction: Rubber conveyor belts are made by layering rubber coatings over a fabric carcass, usually made of polyester, nylon, or cotton. This construction provides the belt with flexibility, strength, and a durable surface that can withstand various environmental conditions and materials.

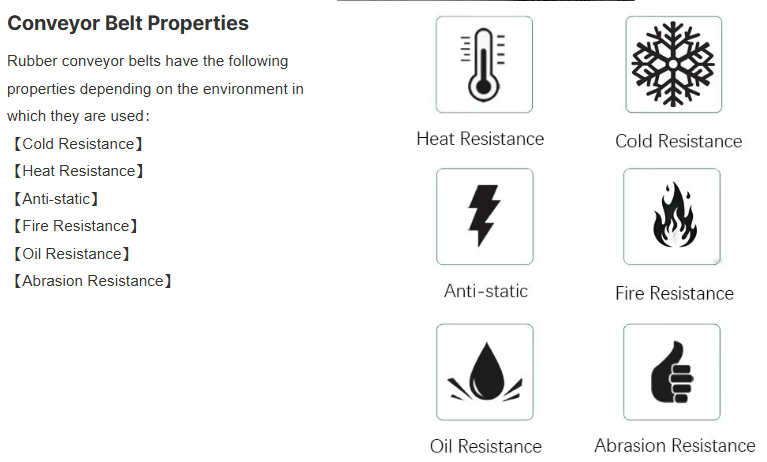

Durability and Wear Resistance: The rubber cover on these belts offers excellent resistance to abrasion, making them suitable for transporting materials that might cause wear on other types of belts. The rubber layer can also be designed to be resistant to oils, chemicals, heat, and moisture, further enhancing the belt's durability.

High Load Capacity: Rubber conveyor belts are capable of handling heavy loads over long distances. Depending on the application, they can transport materials such as aggregates, coal, cement, and grains efficiently and reliably. The belt’s strength is ensured by the fabric reinforcement and the rubber cover.

Flexibility: These belts are highly flexible, allowing them to be used in curved or inclined conveyor systems. This makes them adaptable to various material handling configurations and is particularly useful in manufacturing, mining, and other heavy-duty industries.

Customizable Surface Types: The rubber surface of these belts can be customized to meet specific requirements. For instance, rough top surfaces are available for better grip, while smooth surfaces might be ideal for material flow where friction is less of a concern.

Resistance to Environmental Factors: Rubber conveyor belts can be formulated with different types of rubber compounds to improve their resistance to environmental factors such as temperature extremes, UV exposure, and harsh weather conditions. This makes them highly versatile for both indoor and outdoor applications.

Mining and Quarrying: Rubber conveyor belts are extensively used in mining and quarrying to transport raw materials like coal, ores, sand, and aggregates. Their resistance to impact and wear makes them ideal for these heavy-duty applications.

Cement and Building Materials: These belts are commonly used in the cement industry for transporting bulk materials such as limestone, gypsum, and cement powder. Their resistance to abrasion and ability to handle heavy loads make them an essential component in cement plants.

Agriculture and Food Processing: In agriculture, rubber conveyor belts are used to move grains, vegetables, and fruits. Their smooth surface and gentle handling ensure that delicate materials like food products are transported without damage. Rubber belts are also used in food processing plants to move ingredients or packaged goods.

Manufacturing and Heavy Industry: In manufacturing facilities, rubber conveyor belts help move materials or finished products between different stages of production. Their flexibility and high load-bearing capacity make them suitable for large-scale manufacturing operations.

Logistics and Warehousing: Rubber conveyor belts are commonly used in logistics and warehousing applications to move packages, boxes, and other items. These belts are ideal for sorting and distributing goods efficiently within warehouses and fulfillment centers.

Recycling and Waste Management: Rubber conveyor belts are used in the recycling industry for transporting waste materials or sorting materials such as paper, plastic, and metal. Their durability helps them withstand the challenges of working in the recycling process.

High Durability: The rubber coating provides excellent resistance to wear and abrasion, making rubber conveyor belts suitable for heavy-duty applications where other types of belts may wear out quickly.

Impact Resistance: Rubber belts can absorb shocks and impacts from heavy and abrasive materials, ensuring reliable performance in rugged environments like mining, construction, and waste management.

Heat and Chemical Resistance: Rubber conveyor belts can be formulated with heat-resistant or oil-resistant rubbers, making them ideal for use in industries that deal with high temperatures or chemical exposure, such as power plants and chemical manufacturing.

Flexibility and Versatility: These belts are highly flexible and can be used in various conveyor configurations, including inclined, curved, and horizontal systems. Their adaptability makes them versatile for numerous applications.

Easy to Maintain: Rubber conveyor belts are generally easy to maintain and repair, which helps minimize downtime. With proper maintenance, they can provide long-term, reliable performance.

Safe and Efficient Handling: The rubber surface helps in reducing friction, which allows for smooth material handling and prevents damage to goods, especially when transporting delicate or fragile items like food.

Cost-Effective: Rubber conveyor belts are a cost-effective solution for material handling due to their long lifespan and low maintenance requirements. This makes them a popular choice in industries with high conveyor usage.

Q: Are you a factory or trading company?

A: We are a factory and have export license. Besides, our factory has a number of product lines to provide products with stable production capacity for customers in delivery time.

Q: What information do I need to provide in order to confirm the conveyor rollers order?

A: We work with technical drawings for any non-standard products. If the order is for standard parts, you only have to provide us with the part number so we may define the parts of the order.

Q: Do you have the products in stock?

A: No. All the products are produced according to your order.

Q: Can you produce the hose with my own brand?

A: Yes, we have been offering OEM services to famous manufacturer for several years. Please send email to talk about details.

Q: How long is your delivery time?

A: Generally it is 7-30 days, details depend on your order quantity.

Q: How does your factory do regarding to quality control?

A: Quality is priority. We always attach great importance to quality control from beginning to the end of the production. Every batch conveyor rollers will be carefully inspected before it's packed for shipment.

Q: Can I order a sample?

A: Of course. We can offer regular model roller sample for free, but the freight cost shall be borne by your side. If you want

customized model sample, we'd like you to bear the charge for sample and freight.

Q: What’s benefit will I get?

A: Your client satisfied on the quality.

Your client continued orders.

You can get good reputation from your market and obtain more orders.