Comb Roller is an equipment component widely used in industry, manufacturing, logistics and other fields. It usually consists of a series of closely spaced rollers that resemble the teeth of a comb.

A Comb Roller is a type of roller used in conveyor systems, primarily designed to efficiently guide and support conveyor belts or materials during their movement. The comb roller features a specialized design with comb-like teeth that help manage the alignment of materials, preventing slippage or misdirection of goods on the conveyor belt. This feature is particularly useful for certain types of products that are prone to slipping or misalignment as they travel along a conveyor.

Comb-Like Teeth Design: The roller is equipped with teeth or comb-like projections around its circumference, which help to guide and support items on the conveyor. This design helps keep materials aligned and prevents them from falling off or drifting sideways.

Durability: Comb rollers are constructed using high-strength materials such as steel, stainless steel, or reinforced plastic, ensuring a long service life even in harsh operating conditions. They are resistant to corrosion, abrasion, and wear, providing excellent performance over time.

Versatile Functionality: These rollers are often used in systems that handle a wide range of materials, especially those that are difficult to align or prone to movement, such as boxes, bags, and other irregularly shaped objects.

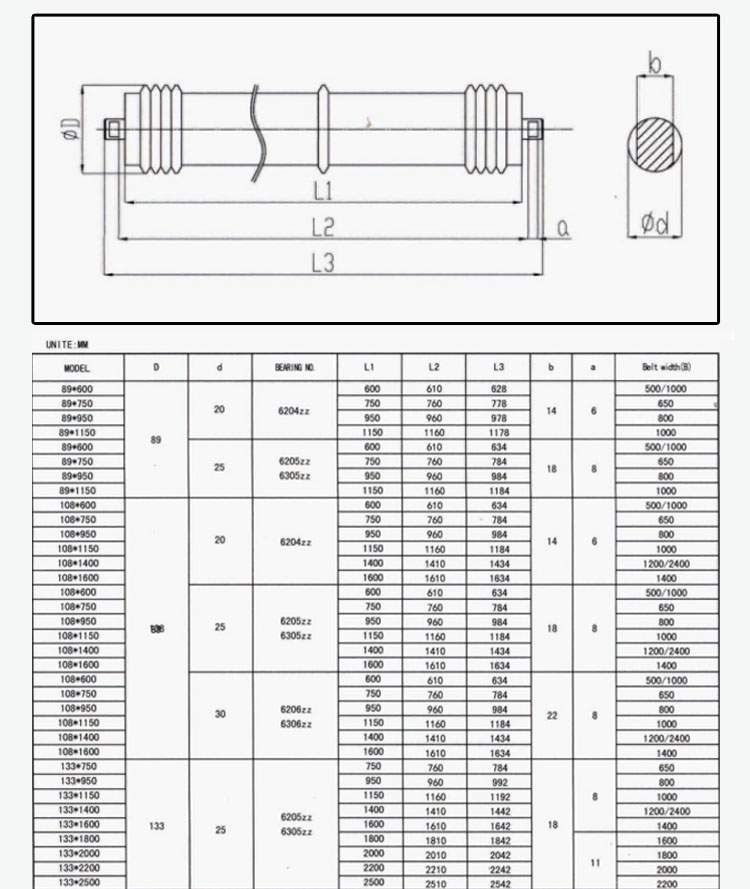

Customizable: Comb rollers can be tailored to meet specific needs, with different sizes, materials, and designs available to suit various conveyor systems or operational environments.

Noise Reduction: The comb roller’s design can contribute to smoother, quieter operation compared to standard rollers, helping to reduce the overall noise in the working environment.

Material Handling: Comb rollers are widely used in material handling applications to keep products aligned and in place while being moved along conveyor systems.

Packaging Industry: In packaging lines, comb rollers help guide packages and products, ensuring they move in the correct direction without misalignment.

Sorting Systems: Ideal for automated sorting systems where products need to be directed accurately to their respective destinations.

Warehousing: Used in warehouses to manage the flow of goods and prevent items from straying off course on conveyor belts.

Improved Alignment: The comb-like teeth prevent products from veering off course, ensuring that items remain aligned on the conveyor.

Enhanced Efficiency: By keeping materials properly aligned, comb rollers minimize downtime, ensuring a continuous and smooth operation.

Durability and Strength: The robust construction ensures a long service life, even under high-load or demanding conditions.

Reduced Wear and Tear: Comb rollers help distribute the load evenly, reducing wear on other components of the conveyor system and extending the overall lifespan of the equipment.

Prevention of Product Damage: The design minimizes the risk of products becoming damaged during transport by maintaining proper alignment and preventing jostling or collisions.

Q: Are you a factory or trading company?

A: We are a factory and have export license. Besides, our factory has a number of product lines to provide products with stable production capacity for customers in delivery time.

Q: What information do I need to provide in order to confirm the conveyor rollers order?

A: We work with technical drawings for any non-standard products. If the order is for standard parts, you only have to provide us with the part number so we may define the parts of the order.

Q: Do you have the products in stock?

A: No. All the products are produced according to your order.

Q: Can you produce the hose with my own brand?

A: Yes, we have been offering OEM services to famous manufacturer for several years. Please send email to talk about details.

Q: How long is your delivery time?

A: Generally it is 7-30 days, details depend on your order quantity.

Q: How does your factory do regarding to quality control?

A: Quality is priority. We always attach great importance to quality control from beginning to the end of the production. Every batch conveyor rollers will be carefully inspected before it's packed for shipment.

Q: Can I order a sample?

A: Of course. We can offer regular model roller sample for free, but the freight cost shall be borne by your side. If you want

customized model sample, we'd like you to bear the charge for sample and freight.

Q: What’s benefit will I get?

A: Your client satisfied on the quality.

Your client continued orders.

You can get good reputation from your market and obtain more orders.